Additive Manufacturing Optimization of Any Thermal or Mechanical Build Issue at Any Scale

Adjoint sensitivity driven optimization enables fast physics based optimization for large scale additive parts. Any model input can be optimized.

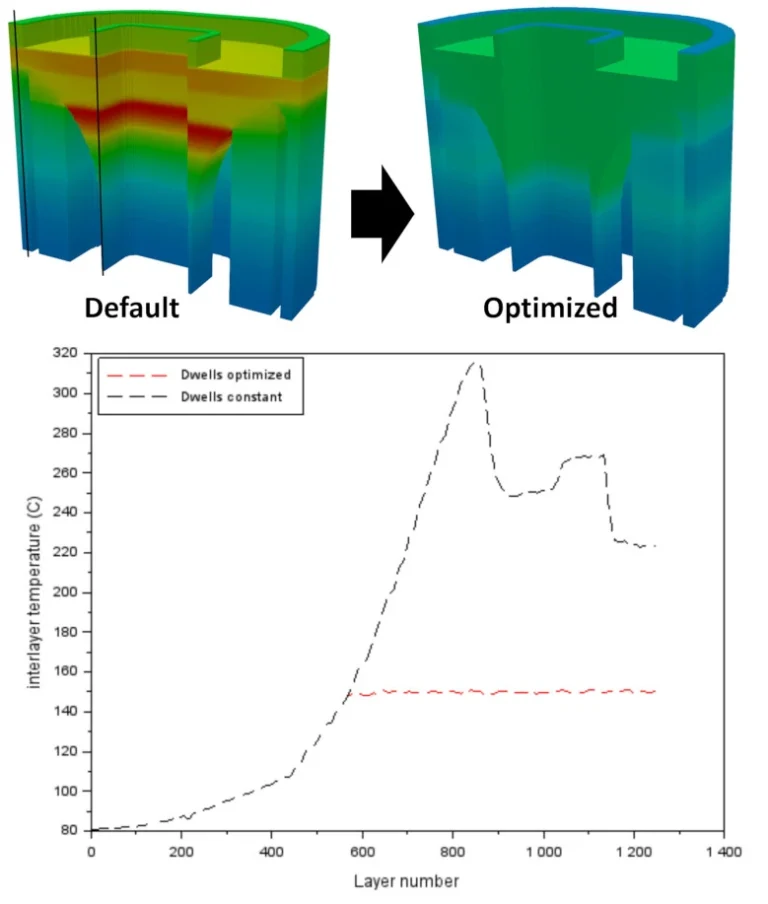

Thermal Dwell Optimization

Power Optimization (Beta)

Support Structure Optimization (Alpha)

Interlayer Temperature Optimized Support Structure

PanX uses adjoint sensitivities to drive support structure optimization.

The criteria in this example is to keep interlayer temperatures below a target threshold, while using minimal support material

This optimization converged after 8 iterations, taking only 31 seconds on an 8 core laptop

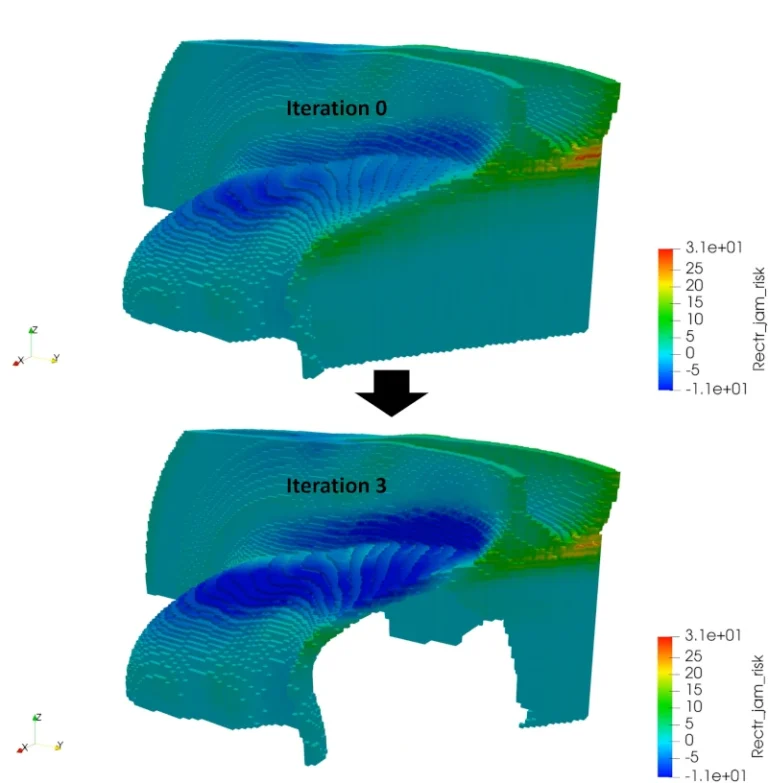

Recoater Clearance Optimized Support Structure

The criteria in this example is to keep interlayer recoater clearance risk below a target threshold, while using minimal support material

Note that the recoater clearance actually risk decreases

This optimization took 8 minutes to converge on an 8 core laptop